In many industrial processes, the

measurement of level is critical. Depending on the nature of the material being measured, this can be a simple or complex task. Several different technologies for sensing level are briefly explained here.

Level Gauges or Sightglasses

|

| Sight Glass or Gauge |

The simplest form of level measurement for direct measurement of level (almost always visually) in a vessel. A level gauge (sightglass) is usually a clear tube connected to the a vessel at the highest and lowest part of the level range. The fluid level inside the vessel will be at the same hight as the level in the tube.

Floats

|

| Float level indicator |

Another very simple approach to level measurement for fluids or solids is the float. The float sits on

top of the material being measured and is visually, magnetically, or electronically located and equated to the level inside the vessel. It is important that the float material be compatible with the process media and that it freely moves on top of the process.

|

| Hydrostatic Pressure |

Hydrostatic Level

A very popular way to measure level because of the ease in equating the pressure of a fluid column with the level inside the vessel. In it's simplest form, a pressure sensor (gauge or transmitter) is attached to the bottom of a vessel and measures the pressure of the column. This pressure reading is then interpreted as level.

|

| Bubbler Principle |

Bubbler Systems

A variation of the hydrostatic pressure method, bubbler systems measure the pressure of a purge gas being injected into the fluid in a vessel through a dip tube. This approach comes in handy when sensing the level of corrosive fluids. The principle of operation is that the amount of pressure to "push" an inert purge gas through the dip tube will change according to the level in that vessel, and therefore can be correlated to the level.

|

| Displacer Level |

Displacer Level

Based upon the laws of buoyancy, a float (either inside its own isolated cage, or hanging in the process directly) is calibrated the the level of the fluid being measured. The displacer is usually a sealed metal tube and hang's in place in the process media. As more of the displacer’s volume becomes submerged, the buoyant force is increased on the making the displacer "lighter".

|

| Echo level measurement |

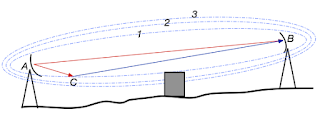

Echo (Ultrasonic, Radar, Laser)

Level measured by bouncing some wave form (sound, light, electromagnetic) off the surface of liquids and measuring their time of flight.

|

| Capacitance level measurement |

Capacitance Level

Capacitive level instruments measure the electrical capacitance of a conductive rod inserted vertically into a process vessel. As process level increases, the capacitance between the rod and the vessel walls increases, causing a signal change in the instruments circuitry.

Weight

Level is measured by knowing the empty weight of a vessel and the full weigh of a vessel and calibrating the points between. The shape of the vessel is can also be a factor.

Industrial level control requires deep knowledge and understanding of many process variables, such as media compatibility, interfaces, head pressures, material densities, and mechanical considerations. It's always recommended that an experienced consultant be involved with the selection and implementation of any industrial level device.

Image attribution: courtesy of "Lessons In Industrial Instrumentation" by Tony R. Kuphaldt