|

All processes should be well understood and evaluated for

maximum performance. |

In

the process control and engineering world, professionals are constantly seeking

ways to optimize their systems and particular process strategies.

Quality-related issues and systems provide chances for process operators to not

only identify potential areas for improvement or correction, but also employ

troubleshooting techniques to make systems perform at the highest level

possible. Traditionally, seven basic tools have been utilized in order to

troubleshoot quality related issues, and serve as simple, yet extremely

effective ways to find solutions.

The

cause and effect diagram is used to investigate and systematically list

potential causes which contribute to an identified effect. Grouping the causes

into different categories visually when attempting to determine the root cause

of a process issue allows the controller to view every component of a system,

and then subsequently investigate how the individual parts act together. This

can be extremely useful when attempting to troubleshoot process control systems.

Check

sheets allow for real-time data collection, either quantitative or qualitative.

A multitude of potential issues, such as dimensions being incorrect in a

product or malfunctions in system technology, are trackable via the check

sheet. The data collected by these sheets allows for an operator to make

sequential decisions regarding the process based on hard data, from which

decisions for optimization can be derived and executed.

The

control chart is a process control tool based on statistics. The basic function

of the chart is to determine whether or not an industrial process is correctly

operating in a state of control, or if the process should be evaluated for

quality-related problems. Basically, the goal of this chart is to determine the

efficacy of the process system and its associated control limits. If the

variation of the process system deviates too much from the expected behavior of

the system, an investigation into the system is required. These charts can be

essential to monitoring process health.

Histograms

are a basic quality tool due to their ability to allow controllers a rough

estimation of probability distributions related to the process in question. If

the variable in question being assessed by the histogram matches the expected behavior,

then the histogram will show said correlation – likewise, if the process is

behaving in an unexpected manner, the histogram will reflect these details. The

Pareto chart is a chart specifically helpful in tracking defects, by category,

which occur most frequently in a certain process. In a process where the

resulting product is defective, the Pareto chart will highlight the defect of

highest occurrence or the most frequent deviation from the expected result.

The

scatter diagram is a tool which allows process controllers to identify whether

a relationship exists between two different quantitative variables and, if

there is a relationship, to help identify what kind of relationship exists

between said variables. The control parameters are established on one axis,

while the dependent variables are established on the other. If the plot can

correctly show the relationship between the variables, then any alterations in

said relationship are identifiable and the related processes can be immediately

examined for cause.

The

last basic tool for process control and quality-related troubleshooting is the

flow chart, which allows for the diagramming of relationships in the process to

track and examine the workflow of the process in question. Together, these seven

items constitute a basic toolbox for optimization and correction of processes,

where their simplicity correlates to effectiveness in understanding particular

process systems.

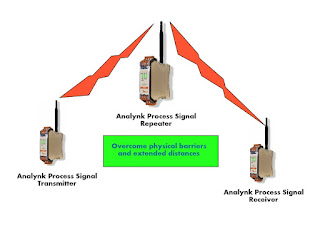

Analynk Wireless manufactures wireless communications equipment for process measurement and control.