|

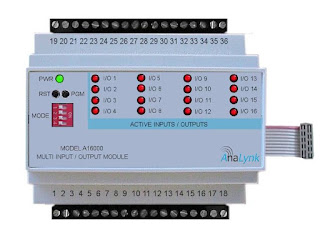

| Genset monitoring application is ideal for use of the A16000 Expansion Module |

A generator set is a risk mitigation asset, intended to prevent loss of operations when certain adverse conditions occur. Power failures are generally infrequent, so the equipment remains idle most of the time. Automatic controls can test run the unit periodically, but continuous monitoring of a few points on the equipment can provide information that increases the assurance that the unit will start when commanded. Delivering the data to an operations center for monitoring and storage for analysis provides a supervisor a snapshot of unit readiness in real time, anytime.

Some items to monitor that can increase your assessment of startup reliability:

- Fuel Level - Clearly, knowing the current fuel level is useful. Being able to read the engine fuel level from your operations center saves technician time and provides a continuous means of estimating available generator runtime.

- Engine Block Heater - Measure the current flowing to the engine block heater to make sure the heater is functioning properly.

- Battery - A voltage reading provides indication of battery health.

- Ambient Temperature - While not essential, logging temperature along with the other items can provide some useful data that may reveal some correlations.

- Generator Controller Fault Indicators - If the generator control system provides any outputs that will indicate detection of a fault, monitoring their status at the facilities office brings the data to where it can be acted upon immediately.

There may be other aspects of a generator set that can be monitored during standby to increase the assurance of a startup on command. A careful assessment of each system in place will reveal the possibilities.

Analynk manufactures all the transmitters and sensors necessary to deliver the data points needed. With many generators located remotely from the point where the data should be delivered, Analynk's wireless communications products can be employed to deliver all the data from the generator to the facilities or operations center without having to install any cabling between the locations.

Reach out to Analynk with your performance or process monitoring and data delivery challenges. Combing your process and facilities knowledge with their product application expertise will produce effective solutions.