Analynk Wireless manufactures hazardous area wireless access point enclosures and hazardous area wireless antennas. Analynk is also a certified UL508A panel manufacturer providing high quality control panels to Ohio and surrounding areas. For more information, visit the Analynk website here or call 614-755-5091.

IIoT and Wireless Connectivity

The Industrial Internet of Things (IIoT) refers to sensors, controllers, actuators, tools, and other devices interconnected with industrial computer applications, including manufacturing and energy management. This connectivity facilitates collecting, distributing, and reviewing data, potentially promoting productivity and quality improvements, and other economic benefits. The IIoT is an evolution of a distributed control system (DCS) that uses cloud computing to refine and optimize process controls, allowing for a greater degree of automation.

In the manufacturing industries, the term industrial internet of things refers to the IoT industrial subset. Improved efficiency, analytics, and the workplace's transformation are future advantages of the industrial Internet of things.

While connectivity and data acquisition is essential for IIoT, they are not the ultimate objectives but rather the basis and path to something larger. Predictive maintenance is an "easier" application of all technology related to current asset and management systems. Smart maintenance systems will minimize unnecessary downtime and improve efficiency, estimated to save up to 12 percent over planned repairs, reduce total maintenance costs by up to 30 percent, and eliminate breakdowns by up to 70 percent.

Wireless connections are increasingly used in IIoT deployments to boost industrial data services' operational communication, such as capturing vast process data, interacting with industrial robots, and monitoring machines/parts/products on and beyond the factory floor.

Industrial users typically play a much more decisive and active role in deciding wireless services in their plants than personal customers in the wireless market. A collaboration between operational technology (OT) engineers, information technology (IT) device architects, and wireless network planners is inherently a wireless system architecture for IIoT applications. The newly founded 5G Alliance for Connected Industries and Automation (5G-ACIA) has provided some inputs from industrial manufacturers in the form of white papers.

There are no one-size-fits-all wireless solutions for industrial use cases as the service requirements, and operating environments may differ vastly from one another. Earlier industrial wireless networks provided connectivity in each single vertical manufacturing sector. As a result, the solutions that function well under the specific service requirements and operating conditions may only yield limited value in different use cases. Wireless success in more emerging IIoT applications will require wireless networks to facilitate the broader and deeper digital contact with industrial systems and provide flexible interfaces and quick deployments while keeping data integrity.

For more information, contact Analynk Wireless.(614) 755-5091

An Excellent White Paper for Understanding Wireless Networking in Hazardous Areas

A potentially explosive atmosphere exists when a gas, vapor, mist, or dust, alone or in combination, occurs in situations where it may ignite under specific conditions. A "hazardous" or "classified" area are places with highly combustible atmospheres that are potentially explosive.

Local and international regulations exist to minimize the risk posed in explosive atmospheres by the energy contained in and required by operating networks and IoT products. A gradual harmonization of these regulations continues to be structured and defined by the IEC and European and US standards.

Industry associations and standards bodies continue to work together to resolve classifying explosive materials and establish standards for the safe operation of networking equipment and IIoT (Industrial Things Internet) products in hazardous areas. Because different organizations perform the work in other areas, understanding which criteria are applicable under different conditions can be difficult.

Aruba Networks has been at the forefront of wireless networking in industrial environments. Their white paper entitled "BUILT TO BLAST: Industrial Internet of Things Hazardous Environment Infrastructure" discusses the various types of dangers, criteria, and conditions that need to be considered before deploying wireless network infrastructure in explosive environments. You can download the white paper here.

The growth of connected industrial IoT devices moves in unison with initiatives to improve operations, maximize efficiency, allow better inventory management, and enhance plant safety. Understanding the unique requirements of wireless networking and communications in hazardous areas is critical. If you have questions about applying wireless networking and instrumentation in hazardous areas, feel free to contact Analynk Wireless. Check out their website at https://analynk.com for contact information.

The Economic Argument of Using Hazardous Area Access Point Enclosures

Many chemical, food processing, refining, mining, petrochemical, and pharmaceutical applications need high-performance Wi-Fi access in potentially explosive environments. Whether it's device telemetry, network access, site-to-site networking, or unified communications, these applications demand the highest Wi-Fi performance possible in the harshest environments.

Some Wi-Fi access points are designed for direct use in explosive conditions without an external protective enclosure. Others are intended for use in non-explosive environments and controlled within a specialized housing specified for that use. The former approach is cost-effective when the underlying technology that drives the equipment is developed, reliable, and unlikely to need an upgrade for years; IoT velocity, positioning, pressure, and temperature sensors fall into that class.

The latter solution – using an outer enclosure – is the most realistic as the underlying wireless technology is rapidly evolving. That's because an explosion-proof enclosure's purchase and installation costs can reflect 4 to 20 times the access point's price. Swapping the access point out, leaving the protective enclosure intact, is significantly less costly than installing a brand new enclosure for some technology upgrades.

The Wi-Fi industry has changed from 802.11n to 802.11ac Wave 1 to 802.11ac Wave 2 in under ten years. Just as no consumer will purchase a new truck based on a 10-year-old design, nor will they consider installing technology-based 802.11n access points from 2007. They will at least use 802.11ac Wave 1, particularly in industrial environments, due to the outstanding multipath performance of 802.11ac in metal presence.

Using standard amortization rates, a consumer wanting to keep up-to-date with the new Wi-Fi technology will upgrade equipment approximately once every four years. If we believe that an access point designed for harsh environments has a list price of $1,500, and with the related Class 1 Division 2 enclosure may list for $3,500. The installation alone (excluding the set-up and commissioning of access points) costs $2,500. In this scenario, buyers can save $4,500 for each access point technology switch when mounting in a hazardous area access point enclosure.

For more information about hazardous area wireless access point enclosures, contact Analynk by calling (614) 755-5091 or visit their website at https://analynk.com.

The Analynk AP427 Dual-Band Hazardous Area Access Point Enclosure for Ubiquiti UAP-AC-M

THE AP427 HAZARDOUS AREA ENCLOSURE HOUSES THE UBIQUITI UAP-AC-M DUAL BAND ACCESS POINT FOR USE IN THE HAZARDOUS AREAS.

The AP427 is designed to house the Ubiquiti UAP-AC-M dual band access point for use in hazardous areas. The enclosure, all hardware, and antennas are rated for Class I, Div 1, groups C & D Hazardous Locations. All hardware, mounting plate, antennas and RF cables are provided to make installation of the access point quick and easy. The enclosure utilizes our proprietary explosion proof CTX series of antennas, two dual band 2.4GHz/5GHz are included.

For more information, contact Analynk Wireless.

(614) 755-5091

8 Major Application Considerations for Industrial Wireless Networks

The laws of physics limit wireless networks. These laws set the boundaries of how much information can be transmitted. Presented below are some key challenges of a wireless communication system.

1 - Wireless Range

The constraints on wireless radio wave transmission are the physical distance, obstacles, and fundamental wavelengths. Obstacles such as metal and concrete severely attenuate radio waves. Higher frequency systems generally have better throughput performance but with less range than systems operating in the lower frequency bands.

2 - Wireless Channel Bandwidth

Wireless communications systems transmit information over finite resources within the electromagnetic (EM) spectrum. EM spectrum is a limited natural resource divided according to the laws and regulations.

3 - Information Data Rate (Bandwidth)

Bandwidth is defined in terms of bits per second and constrained by the communications channel's physics. Realizable bandwidth rarely meets the advertised data rates as channel conditions introduce error. Competition for the channel by other devices on the wireless network creates a delay in channel access.

4 - Latency

In any communication system, transmitting and receiving data takes time. A software program must provide data for transmission, format, modulate, and share it in a wireless device. The electromagnetic waves then take time to spread through space at the speed of light, ultimately arriving at the receiver. Additional time is then required to detect the signal, reconstruct the signal into valid information, and finally deliver it to the client software application. Latency is defined as the actualized duration of information transmission from one application to another within an industrial control system.

5 - Scalability

A wireless network is designed to support a certain number of devices. Scale is an essential factor of industrial wireless networks as it influences the amount of time expected for devices to utilize the finite resources of the wireless channel. Some wireless systems, such as WirelessHART employ scheduling to assure channel availability.

6 - Wireless Security

Security within any industrial wireless deployment, mainly those considered mission-critical, should always be considered in conjunction with the wireless network design and application goals. Security holistically addresses data confidentiality, integrity, and availability issues. Unlike a traditional office setting, data integrity and availability in industrial networks are more significant concerns. For most modern wireless networks, strong encryption is available and should be used inside the factory. To ensure wireless device authentication, authentication protocols should be used to verify access. Wireless networks are also vulnerable to transmission attacks, such as jamming. In mission-critical systems, wireless network isolation is recommended by frequency and distance.

7 - System Availability

The ability of a wireless network to support its intended operation is referred to as system availability. This is typically defined in terms of a percentage availability, such as 99.99%, for which it will stay operational. Attention should be placed on the robustness of devices within the network.

8 - Harsh Industrial Environments

The physical environment usually impacts wireless communications with the presence of obstructions, reflections, and scattering. Such effects lead to multipath transmissions that may not have a direct line-of-sight (LOS) element at times. Industrial environments are more electrically noisy than office and home environments and present far more wireless transmission obstructions and disturbances. Moveable metal items such as forklifts and cranes, narrow aisles between metal shelves, and liquid tanks that can alternate propagation features are examples of this harsh environment. Moreover, depending on the frequency of the produced noise, electrical noise may affect wireless transmissions. Motors and solenoids provide examples of low-frequency noise sources. Arc-generating equipment can make higher-frequency electrical noise.

For wireless transmitters, repeaters, transmitters, antennas, and hazardous area access point enclosures, contact Analynk Wireless by calling (614) 755-5091 or visiting their website at https://analynk.com.

Turnkey Hazardous Area Wireless Enclosure/Access Point Solution: The Analynk AE902

A Class 1 Div 2, ATEX Zone 2 Wireless Access Point Enclosure with Aruba AP 318, Power Supply, Antennas and Optional ISA100A / WirelessHART

Enclosure | Explosion Proof Access Point | ATEX Wifi Access Point

The Analynk AE902 series includes the Aruba AP-318 dual band access point with an optional Honeywell FDAP2 for ISA100A / WirelessHART communication. The Analynk AE902 is certified for use in Class I, Division 2 or ATEX Zone 2 hazardous areas. The unit's hazardous area enclosure protects an Aruba AP318 wireless access point, a dual band access point delivering gigabit Wi-Fi performance to 802.11ac mobile devices in harsh environments. The optional Honeywell FDAP2 is an industrial meshing access point for ISA100 Wireless and/or WirelessHART field instruments.

The Analynk AE902 also includes a PoE (Power over Ethernet) injector and universal input power supply. The enclosure is made of 316 stainless steel and has a NEMA 4X or IP66 rating for harsh conditions. Optional directional hazardous area antennas are available and can be mounted remotely from the enclosure.

For more information, contact Analynk Wireless. Call them at (614) 755-5091 or visit their website at https://analynk.com.

The Analynk AP426 Dual-Band Hazardous Area Access Point Enclosure for the Fortinet FAP-223 Access Point

The AP426 hazardous area enclosure houses the Fortinet FAP-223E dual band access point for use in the hazardous areas.

Analynk Access Point Enclosures for Hazardous Locations and Extreme Working Environments

Analynk Access Point Enclosure for Hazardous Locations: Isolation of Wireless Access Points from Explosive Vapors in Tightly Regulated Industries Including Oil & Gas, Petrochemical, Pharmaceutical and Chemical

The Analynk AP419 Dual-Band Hazardous Area Access Point Enclosure for Cisco Meraki MR84 Access Point

The AP419 hazardous area enclosure houses the Cisco Meraki MR84 dual band access point for use in the hazardous areas.

The AP419 hazardous area enclosure houses the Cisco MR84 dual band access point for use in the hazardous areas. The enclosure and antennas are designed for use in Class I, Division 1 group C & D areas. All hardware, mounting plate, antennas and RF cables are provided to make installation quick and easy. The enclosure utilizes our proprietary explosion proof CTX series of antennas and includes four 2.4GHz/5GHz dual band antennas. The access point is not included with the enclosure.

The Analynk AP417 Dual-Band Hazardous Area Access Point Enclosure for Cisco Aironet 1562E Outdoor Access Point

The AP417 hazardous area enclosure houses the Cisco AIR-AP1562E dual band access point for use in the hazardous areas.

The enclosure and antennas are designed for use in Class I, Division 1 group C & D areas. All hardware, mounting plate, antennas and RF cables are provided to make installation quick and easy. The enclosure utilizes our proprietary explosion proof CTX series of antennas and includes four 2.4GHz/5GHz dual band antennas. The access point is not included with the enclosure.

For more information, contact Analynk Wireless.

(614) 755-5091

NEW! The AP422 Dual-Band Hazardous Area Access Point Enclosure for Cisco 1852E

Analynk Wireless is pleased to introduce the AP422 Dual-Band Hazardous Area Access Point Enclosure for the Cisco 1852E.

The AP422 is designed to house the Cisco 1852E dual band access point for use in hazardous areas. The enclosure, all hardware, and antennas are rated for Class I, Div 1, groups C & D Hazardous Locations. All hardware, mounting plate, antennas and RF cables are provided to make installation of the access point quick and easy. The enclosure utilizes our proprietary explosion proof CTX series of antennas, three dual band 2.4GHz/5GHz are included.

For more information, contact Analynk Wireless.

(614) 755-5091

New Analynk 4G LTE Hazardous Area Antenna Nears Release

Analynk will soon release a new 4G LTE hazardous area antenna to compliment its existing line of rugged, industrial hazardous area antennas. For details, call (614) 755-5091 or email info@analynk.com.

Why 4G?

Sure, everyone's talking about 5G and it's impact on industrial networks. By broadening the scope of applications possible with cellular technologies, there's no doubt 5G will connect industry like never before. However, it won't be soon.

The unfortunate truth is that features specific for industrial 5G use are not expected to be part of the 5G standard until 2021. If you then consider the years it will take to introduce production runs of 5G chips, smooth out production processes, and stabilize their performance in varying applications, you're at least 4-5 years away from meaningful industrial 5G implementation.

In the meantime, non-public networks, owned and managed by large organizations or service providers, will be the most logical and efficient way to solve the challenges of availability, data privacy, reliability, and quick rollouts. This, coupled with backward compatibility from 4G LTE to 5G being a core strategy of the 3GPP consortium, presents a strong argument toward the adoption of 4G LTE networks as the most logical and effcient path forward.

Considering that 4G LTE's momentum continues, and forecasts predict it will continue to grow its user base for years to come, it stands to reason that "4G now" is the perfect bridge for adoption as you move toward Industry 4.0 and 5G.

Analynk to Exhibit and Sponsor Aruba Atmosphere'20

Aruba access points (APs) are well known for their excellent coverage in central and remote sites, locations with high concentrations of Wi-Fi clients, indoors and outdoors, and harsh industrial environments. They are deployed in a wide range of wireless LAN (WLAN) environments world-wide. In the industrial space, many flight line, refinery, oil platform, storage depot, and mining applications require placing access points in an environment that is exposed to gasoline, natural gas, or other explosive gases or vapors.

Analynk manufactures hazardous area access point enclosures designed for Class 1, Division 1 and 2 locations, Groups A, B, C, & D and ATEX Zone 2 areas. Providing Wi-Fi or mesh in these hazardous locations is now accomplished by mounting the AP or MSR inside a compatible Analynk enclosure and connecting approved conduit and cabling.

Atmosphere is the annual Aruba meeting and convention for innovators in the field of wireless networking, wireless security, IoT, mobility and the cloud. Attendees of Atmosphere'20 have an opportunity to meet and rub shoulders with over 3000 peers. The goal of the meeting is to discuss, learn, collaborate and influence the direction of Aruba products with the mission to support Aruba in continuing to build and supply the industry’s best enterprise-class technologies in wireless & wired infrastructure.

Analynk is very proud to be a Silver Sponsor for Atmosphere'20.

Meeting Details:

When: March 22-27, 2020

Where: Caesars Forum Conference Center, Las Vegas, NV

Registration: Click this link.

Product Update: The AE902 Hazardous Area Access Point Now Includes UL C1, D2, Groups A, B, C, & D and ATEX Zone 2

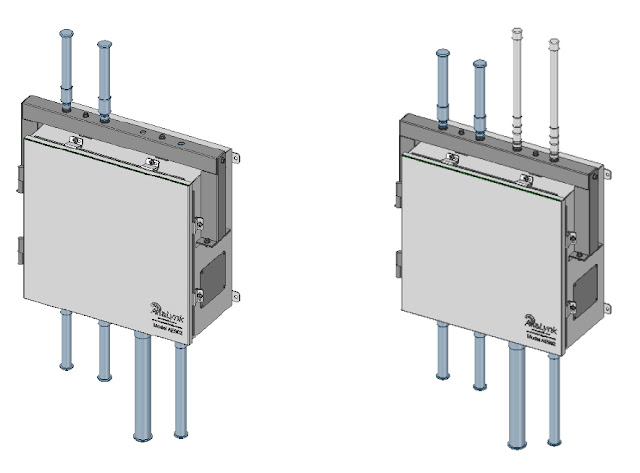

The Analynk AE902 Series Hazardous Area Class 1, Division 2 / ATEX Zone 2, Access Point with Optional ISA100/HART Router

The Analynk AE902 series includes the Aruba AP-318 dual band access point with an optional Honeywell FDAP2 for ISA100A/HART communication. The AE902 is certified for use in Class I, Division 2 or ATEX Zone 2 hazardous areas. A POE injector and universal input power supply are also included. The enclosure is made of 316 stainless steel and has a NEMA 4X or IP56 rating for harsh conditions. Optional directional antennas are available and antennas can be mounted remotely from the enclosure.

Applications:

- Pharmaceuticals

- Oil refineries

- Oil & Gas Platforms

- Chemical Plants

Model: AE902-1A

Model: AE902-2A

Model: AE902-1A-ATEX

Model: AE902-2A-ATEX

Analynk Wireless, LLC

790 Cross Pointe RoadColumbus, OH 43230

614-755-5091 phone

614 -755-5093 fax

www.analynk.com