Analynk Wireless manufactures hazardous area wireless access point enclosures and hazardous area wireless antennas. Analynk is also a certified UL508A panel manufacturer providing high quality control panels to Ohio and surrounding areas. For more information, visit the Analynk website here or call 614-755-5091.

Methods of Isolating Electrical Equipment in Hazardous Areas

Background

BackgroundCombustion or fire is a chemical reaction in which a combustible material combines with an oxidant to release energy. Part of the energy release is used to sustain the explosion, by utilizing existing heat or creating a vacuum to consume more oxygen. Within a hazardous environment there are three elements necessary for a fire or explosion:

- A combustible material also known as a fuel

- Ignition source - electrical arcing or general heat

- An oxidizer also known as oxygen

Another key factor in a fire or explosion are the explosive limits. These are the maximum and minimum concentration needed of a given combustible material to support a fire or explosion. To form an explosive mixture, the hazardous gas must have sufficient concentration levels. The minimum concentration of oxygen to combustible material is known as the lower explosive limit or LEL. If the concentration is below the LEL, it will not be flammable or have enough flammable material present. The same condition would apply if gas concentration is too rich, meaning it will not ignite because it will not have sufficient oxygen to sustain the fire or explosion. This is known as the upper explosive limit, or UEL. It should be noted that different gases will have different threshold limits.

In addition to the explosive limits, each hazardous material will have an autoignition temperature and a flashpoint. The flashpoint is the temperature at which the material will generate sufficient quantity of vapor to form an ignitable mixture. As the liquid is heated and reaches the flashpoint, autoignition could occur. An autoignition is the lowest temperature at which a combustible material will spontaneously ignite in a normal atmosphere. For example, if we have the heating of a combustible liquid, explosive vapors are created. As the material reaches the explosive limits creating the flashpoint. If the general atmosphere is increased, the autoignition temperature, fire, or explosion will occur.

To simplify, the specification of electrical devices into hazardous environments, IEC classification methods utilize autoignition, flashpoint, and explosive limits to place hazardous materials within groups.

The two predominant methods used for classification of hazardous environments are the NEC and IEC standards. IEC and NEC standards both classify the level of risk into three main categories:

- Continuous

- Occasional

- Not normally present

Referring back to the necessary requirements for an explosive triangle, we know we need ignition source, oxygen, gas and or dust combustible material in the correct mixture within the atmosphere. In order to specify electrical devices and hazardous locations, we need to identify the general Zones within each area. When working with liquids or gas, we locate the most hazardous or flammable location directly above the material. Due to the possibility of the valve leaking, at the top of the containment structure we must classify the area as Zone 1. As we move further away from the possible explosive atmospheric condition the Zone classification would be reduced to Zone 2. By altering the combustible material properties to a solid form, the area classification above the material would be Zone 20. If the dust escapes the same failed valve, the external area around the same containment unit would be classified as Zone 21. As we continue to move away from the containment unit and with reduction of Category risk, the new classification for the general area would be Zone 22.

Now that we know combustible materials whether liquid, gas and or dust will have different upper and lower explosive limits, and we understand the general heat could be the ignition source, within the IEC standards the T rating specifies the maximum surface temperature an electrical device will create. As the temperature increases, the associate rating will decrease, meaningless heat will have a higher T rating, while an increase in surface temperature will reduce the T number.

As a recap the IEC standards classify hazardous areas as environments that could contain explosive vapors, gases, and/or dust within the atmosphere. The primary categories provide the risk levels as constant, occasional, and not likely. Since elements have a variety of flammability and the physical properties could be different, IEC standards segment the types of combustible materials into Zone classifications. The most hazardous is Zone 0 or Zone 20. By reducing the risk level to have occasional explosive atmospheres the Zone classification is Zone 1 or Zone 21 and further reduction of Category risks would change the hazards classification to Zone 2 or Zone 22

|

| Flameproof enclosure for wireless access point (Analynk) |

Methods of Isolation/Protection

Let's take a look at each method of protection and the general application. To ensure safety in a given situation, equipment is placed in protective level categories. As mentioned before Category 1 is the highest safety level, making Category 3 the lowest risk and safety level. The general 8 protective methods are:

- Flameproof enclosures

- Sand encapsulation

- Pressurization

- Oil encapsulation

- General encapsulation

- Increased safety

- Intrinsic safety

- Non-sparking

- Power operated equipment

- Switchgear

- Motors

- Any equipment that produces ignition source during normal operation.

Pressurization is a method of protection by which the entry of a surrounding combustible material is prevented by maintaining a protective gas within the enclosure. This is generally accomplished by creating a higher pressure within the enclosure than the surrounding atmosphere. This protective method would be used for any power operated equipment.

Oil encapsulation is a type of protection in which the electrical apparatus or part of the electrical apparatus are immersed within an oil-based fluid. The general application for this type of protection would be used for:

- Switchgear units

- Circuit breakers

- Transformers

- Electrical circuit boards

- Miniature motors

- Valves

Connection and distribution boxes

Luminaires

Measuring instruments and devices that do not normally produce ignition within operation

Intrinsic safety is a protective method to ensure that the available electrical and thermal energy in the system is always low enough that the ignition of the hazardous atmosphere cannot occur. This is achieved by ensuring that only low voltages and currents enter the hazardous area as well as all electrical supply and signal wires are protected by safety barriers. The general application for intrinsic safety would be used for:

- Measuring and control engineering

- Data engineering

- Low electrical valves

- Motors

- Lighting

- Junction boxes

- Electrical equipment

In summary hazardous locations could exist in multiple industries. The geographical location will dictate the general method used for classification. The European Standard or IEC provides guidance of risk into three main categories. These risk levels are then divided into Zones and have numerical values that relate to the possibility of explosive gases or dusts present within the atmosphere. Because combustible material could have a variety of explosive limits, the method of protection will be important. Nevertheless all electrical devices placed within hazardous environments will follow the device markings to ensure fire or explosion does not occur.

Wireless Process Instrumentation and Cloud-based Solutions, Part Two

A standout example of success in wireless and cloud-based tech is the adoption and growth of ADC. ADC is an abbreviation for Automated Device Commissioning, sometimes referred to as Smart Commissioning. From a practical standpoint, it is a set of engineering techniques and processes to check, inspect and test every operational component of a project. Workflows incorporating lean engineering can benefit from designing instrument configurations before the hardware is actually delivered to the facility.

ADC/Smart Commissioning can be used to: Reduce commissioning time to a fraction of the original hours needed; mechanically bind control configuration; reduce the need to verify I/O assignments; help avoid costly errors in wiring and termination; and automate intelligent device testing and documentation.

Use of ADC/Smart Commissioning promotes efficiency for automation projects. Engineers used to have to deal with repetitive and complicated tasks to get the project set up. Now with this new approach, assisted by wireless and the cloud, teams of engineers can work on the project collectively, and at the same time, without needing to be physically at the same site.

As capable engineers and maintenance personnel continue to retire from the workforce, and as manufacturing companies are forced to accomplish their work with fewer experienced employees, wireless technology and cloud-based tools facilitate greater efficiency through equipment optimization, performance tracking, safety monitoring, and process reliability.

Analynk Wireless

https://analynk.com

(614) 755-5091

Analynk Wireless

https://analynk.com

(614) 755-5091

Wireless Process Instrumentation and Cloud-based Solutions

Wireless technologies and cloud computing systems are changing industrial communications. Industrial wireless networks and cloud-based tools, simply stated, allow manufacturing plants to do more with fewer people.

This two-part article delves into the recent trends in the use of cloud-based tools and wireless networks to help plant operators improve their application validation, improve their diagnostic selection of instrumentation, and improve device commissioning.

The benefits of wireless and mobile communications is clear. Engineers and other factory personnel can input data wirelessly via a smart phone, or a laptop computer so they can have their specific requirements recorded. Collaboration with other team members is possible, through the cloud, to determine the optimum set up for the project devices to streamline engineering decisions (and to avoid expensive mistakes upfront in the project). Information in the cloud may also be equipped for instant duplication, so projects that have many identical device configurations can be rapidly repeated.

Using a cloud-based and wireless network approach improves success in installing large numbers of new field instruments, which is common for unit expansion. Other benefits of adapting cloud-based services and wireless networks for prices control include:

The paradigm for instrumentation setup is changing dramatically. Cloud-based tools and wireless communications are optimizing manufacturing operations and delivering capital projects cost effectively, efficiently, and as rapidly as possible.

Under increasing pressure for improved quality, safety, and profits companies are migrating toward cloud-based application, data storage and wireless networking. These new technologies are playing a key role in improving safety, lowering operating costs, providing real-time performance data, and continuously monitor processes.

This two-part article delves into the recent trends in the use of cloud-based tools and wireless networks to help plant operators improve their application validation, improve their diagnostic selection of instrumentation, and improve device commissioning.

The benefits of wireless and mobile communications is clear. Engineers and other factory personnel can input data wirelessly via a smart phone, or a laptop computer so they can have their specific requirements recorded. Collaboration with other team members is possible, through the cloud, to determine the optimum set up for the project devices to streamline engineering decisions (and to avoid expensive mistakes upfront in the project). Information in the cloud may also be equipped for instant duplication, so projects that have many identical device configurations can be rapidly repeated.

Using a cloud-based and wireless network approach improves success in installing large numbers of new field instruments, which is common for unit expansion. Other benefits of adapting cloud-based services and wireless networks for prices control include:

- A convenient way to share and collaborate in real-time. Multiple users can visualize the transmitter configuration though a link. This saves staff time and reduces travel time for support people.

- If a beginning user has an underdeveloped knowledge of the application, the cloud can provide readily accessible information such as compatibility charts, specification sheets, code requirements, etc … .

- Generation of a standard data sheet so engineers don't have to spend as much time on data entry. The data sheet can be stored to support the user's necessary documentation and audit trail.

The paradigm for instrumentation setup is changing dramatically. Cloud-based tools and wireless communications are optimizing manufacturing operations and delivering capital projects cost effectively, efficiently, and as rapidly as possible.

Under increasing pressure for improved quality, safety, and profits companies are migrating toward cloud-based application, data storage and wireless networking. These new technologies are playing a key role in improving safety, lowering operating costs, providing real-time performance data, and continuously monitor processes.

Introduction to WirelessHART

WirelessHART is a subset of the HART industrial instrument communication standard as of version 7, communicating process data over 2.4 GHz radio waves. Individual instruments communicate with a common “gateway” device serving as an interface between the wireless network and a wired network or a host control system. In addition to this, though, individual WirelessHART devices also form links with one another, so that the network data routes look like a “mesh” with all nearby nodes interconnected in addition to connecting with the gateway:

In a mesh network, devices (nodes) perform double-duty as repeaters to relay data from other instruments to the gateway as needed. In other words, data transmitted from one WirelessHART instrument may not be directly received by the gateway device if that path is blocked or too far away. Instead, the data may “hop” from one device to another nearby, which then re-broadcasts that information to the gateway via a clearer path.

The purpose of a mesh network is to provide redundant data pathways in case of device failure or changes in the environment interrupting radio communication between devices. In this way, data packets may be re-routed to the gateway if the shortest route fails, in a manner similar to how Terminal Control Protocol (TCP) and Internet Protocol (IP) work together to route data segments from source to destination over the “mesh” of the Internet. This feature is often referred to in WirelessHART technical literature as the self-healing property of the mesh network.

According to the HART Foundation, reliability for a well-designed WirelessHART mesh network is 99.7300204% minimum, and typically greater than 99.9999998%.

With each WirelessHART field instrument capable of functioning as a radio repeater, the potential exists to form wireless networks larger in size than the maximum broadcast/reception range of any one device. This illustration shows what is possible:

An important consideration when planning a WirelessHART network is battery life. With the main purpose of wireless field instruments being the elimination of wired connections to the host system, the field instruments cannot rely on a host system for their electrical power needs. Lithium-based batteries currently fulfill this role as primary power source, with life expectancies of several years. Interestingly, the amount of energy required by a WirelessHART device to transmit radio-frequency data is small compared to the energy required to power its essential instrument functions (e.g. pressure measurement, temperature measurement). This means a WirelessHART device operating as a radio repeater (in addition to being a measurement device) adds little burden to its battery.

Perhaps the greatest challenge in sustaining any wireless field instrument network is ensuring network integrity despite unending changes in the physical environment around the instruments. Remember that this is an industrial, field-instrument wireless network designed to be installed in less-than-ideal physical environments. These wireless devices must somehow reliably communicate with each other despite interference from high-power electrical devices (e.g. variable-frequency motor drive units), while mounted on or near metal objects such as girders, pipes, pipe racks, large vessels, motors, enclosures, shelters, and electrical conduits. Even the ground of an industrial environment can be an impediment to robust radio communication: steel-reinforced concrete and electrical grounding grids form what is essentially a solid “ground plane” that will interfere with WirelessHART devices mounted too close to ground level. Added to all this spatial complexity is the continual presence of large vehicles and other moving machines (cranes, forklifts, manlifts, etc.). It is not uncommon for scaffolding to be temporarily erected for maintenance work in industrial areas, presenting yet one more obstacle for RF signals.

In answer to these challenges is an integral and essential component of a WirelessHART network called the Network Manager: an advanced digital algorithm usually executed by the network gateway’s microprocessor. The purpose of the Network Manager is to manage the details of the network automatically, “tuning” various parameters for optimum reliability and data throughput. Among other tasks, the Network Manager assigns “timeslots” for individual devices to transmit, determines the frequency-hopping schedule, detects and authenticates new devices added to the network, dynamically adjusts device transmission power, and selects alternative routes between devices.

In a sense, the Network Manager in a WirelessHART network continually audits and tunes the RF system in an attempt to maximize reliability. The Network Manager’s functionality does not substitute for good planning during the design phase of the WirelessHART network, but it does eliminate the need for a human technician or engineer to continuously monitor the network’s performance and make the small adjustments necessary to compensate for changing conditions. When changes occur in a WirelessHART network that cannot be compensated by the Network Manager, the real-time statistics provided by the Network Manager are invaluable to the technician or engineer assigned to update the network.

Reprinted from "Lessons In Industrial Instrumentation" by Tony R. Kuphaldt – under the terms and conditions of the Creative Commons Attribution 4.0 International Public License.

In a mesh network, devices (nodes) perform double-duty as repeaters to relay data from other instruments to the gateway as needed. In other words, data transmitted from one WirelessHART instrument may not be directly received by the gateway device if that path is blocked or too far away. Instead, the data may “hop” from one device to another nearby, which then re-broadcasts that information to the gateway via a clearer path.

The purpose of a mesh network is to provide redundant data pathways in case of device failure or changes in the environment interrupting radio communication between devices. In this way, data packets may be re-routed to the gateway if the shortest route fails, in a manner similar to how Terminal Control Protocol (TCP) and Internet Protocol (IP) work together to route data segments from source to destination over the “mesh” of the Internet. This feature is often referred to in WirelessHART technical literature as the self-healing property of the mesh network.

According to the HART Foundation, reliability for a well-designed WirelessHART mesh network is 99.7300204% minimum, and typically greater than 99.9999998%.

With each WirelessHART field instrument capable of functioning as a radio repeater, the potential exists to form wireless networks larger in size than the maximum broadcast/reception range of any one device. This illustration shows what is possible:

An important consideration when planning a WirelessHART network is battery life. With the main purpose of wireless field instruments being the elimination of wired connections to the host system, the field instruments cannot rely on a host system for their electrical power needs. Lithium-based batteries currently fulfill this role as primary power source, with life expectancies of several years. Interestingly, the amount of energy required by a WirelessHART device to transmit radio-frequency data is small compared to the energy required to power its essential instrument functions (e.g. pressure measurement, temperature measurement). This means a WirelessHART device operating as a radio repeater (in addition to being a measurement device) adds little burden to its battery.

Perhaps the greatest challenge in sustaining any wireless field instrument network is ensuring network integrity despite unending changes in the physical environment around the instruments. Remember that this is an industrial, field-instrument wireless network designed to be installed in less-than-ideal physical environments. These wireless devices must somehow reliably communicate with each other despite interference from high-power electrical devices (e.g. variable-frequency motor drive units), while mounted on or near metal objects such as girders, pipes, pipe racks, large vessels, motors, enclosures, shelters, and electrical conduits. Even the ground of an industrial environment can be an impediment to robust radio communication: steel-reinforced concrete and electrical grounding grids form what is essentially a solid “ground plane” that will interfere with WirelessHART devices mounted too close to ground level. Added to all this spatial complexity is the continual presence of large vehicles and other moving machines (cranes, forklifts, manlifts, etc.). It is not uncommon for scaffolding to be temporarily erected for maintenance work in industrial areas, presenting yet one more obstacle for RF signals.

In answer to these challenges is an integral and essential component of a WirelessHART network called the Network Manager: an advanced digital algorithm usually executed by the network gateway’s microprocessor. The purpose of the Network Manager is to manage the details of the network automatically, “tuning” various parameters for optimum reliability and data throughput. Among other tasks, the Network Manager assigns “timeslots” for individual devices to transmit, determines the frequency-hopping schedule, detects and authenticates new devices added to the network, dynamically adjusts device transmission power, and selects alternative routes between devices.

In a sense, the Network Manager in a WirelessHART network continually audits and tunes the RF system in an attempt to maximize reliability. The Network Manager’s functionality does not substitute for good planning during the design phase of the WirelessHART network, but it does eliminate the need for a human technician or engineer to continuously monitor the network’s performance and make the small adjustments necessary to compensate for changing conditions. When changes occur in a WirelessHART network that cannot be compensated by the Network Manager, the real-time statistics provided by the Network Manager are invaluable to the technician or engineer assigned to update the network.

Reprinted from "Lessons In Industrial Instrumentation" by Tony R. Kuphaldt – under the terms and conditions of the Creative Commons Attribution 4.0 International Public License.

What Are Industrial Control Systems?

Control systems are computer-based systems that are used by many infrastructures and industries to monitor and control sensitive processes and physical functions. Typically, control systems collect sensor measurements and operational data from the field, process and display this information, and relay control commands to local or remote equipment. In the electric power industry they can manage and control the transmission and delivery of electric power, for example, by opening and closing circuit breakers and setting thresholds for preventive shutdowns. Employing integrated control systems, the oil and gas industry can control the refining operations on a plant site as well as remotely monitor the pressure and flow of gas pipelines and control the flow and pathways of gas transmission. In water utilities, they can remotely monitor well levels and control the wells’ pumps; monitor flows, tank levels, or pressure in storage tanks; monitor water quality characteristics, such as pH, turbidity, and chlorine residual; and control the addition of chemicals. Control system functions vary from simple to complex; they can be used to simply monitor processes—for example, the environmental conditions in a small office building—or manage most activities in a municipal water system or even a nuclear power plant.

In certain industries such as chemical and power generation, safety systems are typically implemented to mitigate a disastrous event if control and other systems fail. In addition, to guard against both physical attack and system failure, organizations may establish back-up control centers that include uninterruptible power supplies and backup generators.

There are two primary types of control systems. Distributed Control Systems (DCS) typically are used within a single processing or generating plant or over a small geographic area. Supervisory Control and Data Acquisition (SCADA) systems typically are used for large, geographically dispersed distribution operations. A utility company may use a DCS to generate power and a SCADA system to distribute it.

A control system typically consists of a “master” or central supervisory control and monitoring station consisting of one or more human-machine interfaces where an operator can view status information about the remote sites and issue commands directly to the system. Typically, this station is located at a main site along with application servers and an engineering workstation that is used to configure and troubleshoot the other control system components. The supervisory control and monitoring station is typically connected to local controller stations through a hard-wired network or to remote controller stations through a communications network—which could be the Internet, a public switched telephone network, or a cable or wireless (e.g. radio, microwave, or Wi-Fi) network. Each controller station has a Remote Terminal Unit (RTU), a Programmable Logic Controller (PLC), DCS controller, or other controller that communicates with the supervisory control and monitoring station. The controller stations also include sensors and control equipment that connect directly with the working components of the infrastructure—for example, pipelines, water towers, and power lines. The sensor takes readings from the infrastructure equipment—such as water or pressure levels, electrical voltage or current—and sends a message to the controller. The controller may be programmed to determine a course of action and send a message to the control equipment instructing it what to do—for example, to turn off a valve or dispense a chemical. If the controller is not programmed to determine a course of action, the controller communicates with the supervisory control and monitoring station before sending a command back to the control equipment. The control system also can be programmed to issue alarms back to the operator when certain conditions are detected. Handheld devices, such as personal digital assistants, can be used to locally monitor controller stations. Experts report that technologies in controller stations are becoming more intelligent and automated and communicate with the supervisory central monitoring and control station less frequently, requiring less human intervention.

In certain industries such as chemical and power generation, safety systems are typically implemented to mitigate a disastrous event if control and other systems fail. In addition, to guard against both physical attack and system failure, organizations may establish back-up control centers that include uninterruptible power supplies and backup generators.

There are two primary types of control systems. Distributed Control Systems (DCS) typically are used within a single processing or generating plant or over a small geographic area. Supervisory Control and Data Acquisition (SCADA) systems typically are used for large, geographically dispersed distribution operations. A utility company may use a DCS to generate power and a SCADA system to distribute it.

A control system typically consists of a “master” or central supervisory control and monitoring station consisting of one or more human-machine interfaces where an operator can view status information about the remote sites and issue commands directly to the system. Typically, this station is located at a main site along with application servers and an engineering workstation that is used to configure and troubleshoot the other control system components. The supervisory control and monitoring station is typically connected to local controller stations through a hard-wired network or to remote controller stations through a communications network—which could be the Internet, a public switched telephone network, or a cable or wireless (e.g. radio, microwave, or Wi-Fi) network. Each controller station has a Remote Terminal Unit (RTU), a Programmable Logic Controller (PLC), DCS controller, or other controller that communicates with the supervisory control and monitoring station. The controller stations also include sensors and control equipment that connect directly with the working components of the infrastructure—for example, pipelines, water towers, and power lines. The sensor takes readings from the infrastructure equipment—such as water or pressure levels, electrical voltage or current—and sends a message to the controller. The controller may be programmed to determine a course of action and send a message to the control equipment instructing it what to do—for example, to turn off a valve or dispense a chemical. If the controller is not programmed to determine a course of action, the controller communicates with the supervisory control and monitoring station before sending a command back to the control equipment. The control system also can be programmed to issue alarms back to the operator when certain conditions are detected. Handheld devices, such as personal digital assistants, can be used to locally monitor controller stations. Experts report that technologies in controller stations are becoming more intelligent and automated and communicate with the supervisory central monitoring and control station less frequently, requiring less human intervention.

Checklists for Industrial Wireless Systems Deployments

The document "Guide to Industrial Wireless Checklists", developed by the National Institute for Standards and Technology, is intended to be a practical guide used by engineers and managers facilitating them to go through the process of defining the objectives of their wireless systems and examining the environments where the wireless systems are to be deployed, then helping them in selecting, designing, deploying, and monitoring the wireless systems using existing technology in a factory.

Checklists from the above referenced document have been culled and available here for download.

Checklists from the above referenced document have been culled and available here for download.

Network Backbone Basics: Hubs, Bridges, Switches, and Gateways

As the process industry steadily moves to wireless networking components, its important to understand the basics. This post and the video below describe four key backbone components for data networking.

Signal flow and data transfer are assisted within a network by various devices known as backbones. The four different backbone devices are hubs, bridges, switches, and gateways. Each device transports data in a specific way.

A hub is a centralized connecting device. Often located at a center of a star network that automatically rebroadcasts any signal or data that it receives from one device to all other devices on the network. Because all the devices connected to a hub are competing for media usage, it's possible for collisions to occur when two devices send transmissions simultaneously. For this reason, it's important to avoid using a hub for messaging that requires immediate response.

Another network backbone device is called a bridge. Network bridges are smart devices that process and record information about signal traffic between devices in the networks. The bridge then uses this information to determine the most efficient path for data transfer, between a transmitting and a receiving device, without having to send it to every device in the network.

A switch is a multi-port network bridge that uses packet switching to forward data to one or multiple specific devices. Because more than one transmission can occur at a time, switch operating speeds are very fast. Switches are also full duplex devices that allow data signals to flow simultaneously in both directions. This eliminates the risk of data collisions that may occur in other network backbone devices.

When two segments of the same network have different communication formats a gateway is needed to connect them. A gateway performs a conversion function so that a computer on an Ethernet network using a TCP/IP protocol may communicate with a PLC on a subnet using the ControlNet protocol. Even though these two protocols are incompatible, the gateway can connect them on the same network and allow them to function together. Hubs, bridges, switches, and gateways - the backbones of networking - perform individual and important functions in keeping networks performing at their highest level.

https://analynk.com

(614) 755-5091

Signal flow and data transfer are assisted within a network by various devices known as backbones. The four different backbone devices are hubs, bridges, switches, and gateways. Each device transports data in a specific way.

A hub is a centralized connecting device. Often located at a center of a star network that automatically rebroadcasts any signal or data that it receives from one device to all other devices on the network. Because all the devices connected to a hub are competing for media usage, it's possible for collisions to occur when two devices send transmissions simultaneously. For this reason, it's important to avoid using a hub for messaging that requires immediate response.

Another network backbone device is called a bridge. Network bridges are smart devices that process and record information about signal traffic between devices in the networks. The bridge then uses this information to determine the most efficient path for data transfer, between a transmitting and a receiving device, without having to send it to every device in the network.

A switch is a multi-port network bridge that uses packet switching to forward data to one or multiple specific devices. Because more than one transmission can occur at a time, switch operating speeds are very fast. Switches are also full duplex devices that allow data signals to flow simultaneously in both directions. This eliminates the risk of data collisions that may occur in other network backbone devices.

When two segments of the same network have different communication formats a gateway is needed to connect them. A gateway performs a conversion function so that a computer on an Ethernet network using a TCP/IP protocol may communicate with a PLC on a subnet using the ControlNet protocol. Even though these two protocols are incompatible, the gateway can connect them on the same network and allow them to function together. Hubs, bridges, switches, and gateways - the backbones of networking - perform individual and important functions in keeping networks performing at their highest level.

https://analynk.com

(614) 755-5091

Wireless Instrumentation for the Process Control Industry

Analynk wireless instruments have been successfully implemented in process control applications including temperature measurements, 4 to 20mA bridges, discrete inputs/outputs, pulse inputs, lighting and pump controls. Contact Analynk Wireless today to discuss your plant's wireless requirements.

614-755-6091

Wireless for Safety

Wireless systems may be useful to enhancing the safety profile within a factory operation. These systems can be used to prevent injury through improved communication and enhanced situational awareness within the factory. Wireless safety systems are used in many applications including those designed to prevent chemical handling mishaps, avoid heavy equipment accidents such as “struck-by, and back-over” incidents, prevent falls through active position monitoring and safety interconnects, provide situational awareness within confined spaces, and improve safety for non-employees.

Along with adaption of wireless sensor networks for industrial automation, there are more applications of wireless technology created by users after they are more familiar and comfortable with the wireless technology. Also because of the strong benefits of wireless applications that can save project execution time and cost, more and more wireless has been used for secondary or backup systems for time-critical application such as safety or control applications. Based on this movement, ISA-84 working group (WG) 8 developed a technical report on wireless for safety systems other than those of a safety integrated system (SIS), i.e., those systems with a system integrity level (SIL) rating below ten. The technical report describes the additional elements needed to be addressed when wireless technology is used in an Independent Protection Layer (IPL). Refer to the ISA technical report TR84.00.08-2017 Guidance for Application of Wireless Sensor Technology to Non-SIS Independent Protection Layers for more information.

Along with adaption of wireless sensor networks for industrial automation, there are more applications of wireless technology created by users after they are more familiar and comfortable with the wireless technology. Also because of the strong benefits of wireless applications that can save project execution time and cost, more and more wireless has been used for secondary or backup systems for time-critical application such as safety or control applications. Based on this movement, ISA-84 working group (WG) 8 developed a technical report on wireless for safety systems other than those of a safety integrated system (SIS), i.e., those systems with a system integrity level (SIL) rating below ten. The technical report describes the additional elements needed to be addressed when wireless technology is used in an Independent Protection Layer (IPL). Refer to the ISA technical report TR84.00.08-2017 Guidance for Application of Wireless Sensor Technology to Non-SIS Independent Protection Layers for more information.

Reprinted from "Guide to Industrial Wireless Systems Deployments" by the National Institute of Standards and Technology. Get your copy here.

Business Case for Industrial Wireless

One of the key enablers of factory automation is the availability of wireless radio frequency devices. Some applications of radio frequency devices include process control, oil and gas refineries, pharmaceuticals, food and beverage, autonomous guided vehicles (AGVs) control, slotted microwave guides, pendants to control cranes and machine tools, active and passive radio frequency identifier (RFID) for tracking parts, tools and consumables, wireless barcode readers, remote sensing of critical process parameters, mobile telephony, door openers, emergency communication, and general factory Wi-Fi for internet connectivity. In addition, devices not directly associated with the manufacturing process such as microwave ovens and mobile telephone hot spots must be included when designing a factory wireless system. As useful as wireless communications is, it must be recognized that spectrum is limited and there must be judicious choices about when it should be used, and when wired connections are preferable.

In general terms, wireless (as with any upgrade to a factory or enterprise system) should satisfy a requirement related to quality, reliability, efficiency, safety, regulation, or environment as shown in Table 4. The requirements pertain to the business enterprise which in the case of a manufacturing operation means the plant or factory. A wireless deployment should be designed to satisfy one of the key business concerns listed.

Table 4. Purposes for initiating a wireless systems deployment

Reprinted from "Guide to Industrial Wireless Systems Deployments" by the National Institute of Standards and Technology. Get your copy here.

In general terms, wireless (as with any upgrade to a factory or enterprise system) should satisfy a requirement related to quality, reliability, efficiency, safety, regulation, or environment as shown in Table 4. The requirements pertain to the business enterprise which in the case of a manufacturing operation means the plant or factory. A wireless deployment should be designed to satisfy one of the key business concerns listed.

Table 4. Purposes for initiating a wireless systems deployment

- Functionality - Is wireless required to achieve an aspect of function within the factory operation? For example, does the factory require a mobility to achieve a goal?

- Reliability - Is reliability of the production line improved? The ability to manufacture products, parts or assemblies which conform to the engineering definition, and can demonstrate conformity.

- Safety - Are people or equipment made safer? The ability of employees to perform their jobs free from recognized hazards including falls, hazardous energy, confined space, ergonomics, and hazardous materials, and being able to demonstrate compliance with all safety regulations.

- Efficiency - The ability to meet target costs and continue forever to reduce unit production costs.

- Quality - The ability to manufacture parts and assemblies which conform to the engineering definition, and be able to demonstrate conformity.

- Environment - The ability to demonstrate compliance with applicable government regulations at the city, county, state, and federal level.

Reprinted from "Guide to Industrial Wireless Systems Deployments" by the National Institute of Standards and Technology. Get your copy here.

Analynk A75x RF Industrial Wireless DIN System

|

| Analynk A75x |

MODEL NUMBERS:

- A750 Receiver

- A750-Mod (RS232/485)

- A753 Transmitter

- A759 Repeater

- A753-PL Transmitter (pulse)

- A750-PL Reciever (pulse)

- A753-LP Transmitter (900MHz 50mW)

- A750-LP Receiver (900MHz 50mW)

- 35mm DIN rail mount

- Standard 1W long range output, optional 50mW & 63mW

- Removable 2.0dBi dipole antenna

- DIP switch selectable channels

- Signal Strength indicator

- Repeaters available

- No software required

- Factory configured for your application

- Remote 4-20mA installation

- Redundant 4-20mA outputs

- Temperature monitoring

- Tank level monitoring

- Remote switch monitor

- Pulse transmission

- Remote alarms

- Rotating devices (e.g. kilns)

- Temporary 4-20mA

For more information, contact Analynk Wireless by visiting https://analynk.com or by calling (614) 755-5091.

Glossary of Terms in Wireless Networks in Process Control

Below is a list of terminology, abbreviations, and acronyms used in wireless network technology applied to process control.

- 6LoWPAN

- IPv6 Low power Wireless Personal Area Networks

- ARPA

- Advanced Research Projects Agency

- ARUBA

- Refers to Aruba Wireless Networks, now a Hewlett Packard Enterprise company.

- BLIP

- Berkeley Low-power IP stack

- CAP

- Contention Access Period

- CFP

- Contention Free Period

- CISCO

- A company that develops, manufactures and sells networking equipment.

- CSMA-CA

- Carrier Sense Multiple Access with Collision Avoidance

- DAO

- Destination Advertisement Objects

- DIO

- DAG Information Object

- DIS

- DAG Information Solicitation

- DODAG

- Destination Oriented Directed Acyclic Graph

- DSN

- Distributed Sensor Network

- ETX

- Expected Transmission count

- GTS

- Guaranteed Time Slot

- HBN

- Hydrobionet

- ICMP

- Internet Control Message Protocol

- LLN

- Low power Lossy Networks

- MAC

- Media Access Control

- MBR

- Membrane Bioreactor

- MEM

- Micro electromechanical

- MERU

- Refers to Meru Networks, a supplier of wireless local area networks (WLANs).

- MOTOROLA

- A company that designed and sold wireless network equipment.

- MRHOF

- Minimum Rank Objective Function with Hysteresis

- NCS

- Network Controlled System

- OF

- Objective Functions

- OS

- Operating System

- PID

- Proportional-integral-derivative controller

- PRR

- Packet Reception Ratio

- REPEATER

- Device that takes an existing signal from a wireless router or wireless access point for rebroadcasting.

- RPL

- Routing Protocol for Low-Power and Lossy Networks

- RSSI

- Received Signal Strength Indication

- WBN

- Wireless Biosensor & Actuator Network

- WIFI

- Technology for radio wireless local area networking of devices based on the IEEE 802.11 standards.

- WINS

- Wireless Integrated Network Sensors

- WIRELESS ACCESS POINT

- A networking device that allows a Wi-Fi device to connect to a wired network to create a second network.

- WSN

- Wireless Sensor Network

- ZIGBEE

- Popular, low-cost, low-power wireless mesh networking standard.

- Z-WAVE

- Tightly controlled mesh network that caters to the smart home and smart building space.

Happy 4th of July from Analynk!

"We hold these truths to be self-evident, that all men are created equal, that they are endowed by their Creator with certain unalienable Rights, that among these are Life, Liberty and the pursuit of Happiness."

Thomas Jefferson

Process Control and Wireless Networks

Industrial plants, factories and process automation systems are increasingly deploying information and communications technologies to facilitate data sharing and analysis in integrated control networks. Despite the harsh process control environment, signal propagation loss and radio frequency (RF) interference, wireless connections provide fast and easy access to a variety of field instruments and reduce network installation costs and ongoing maintenance outlays. This serves as an incentive for the adoption of industrial wireless networks based on industry standards such as ISA100.11a, a wireless networking technology standard developed by the ISA (International Society of Automation) and the WirelessHART, a wireless sensor networking technology based on the Highway Addressable Remote Transducer Protocol (known as HART). Wide-scale adoption proceeds cautiously though, as industrial environments vary widely and process control systems exhibit a multitude of critical wireless networking requirements, such as:

In lieu of laying down miles of cables to connect hundreds of field instruments, industrial wireless communication networks provide wireless connections with customized network topology, allow for plug-and-play configuration, and offer lower installation and maintenance costs.

Compared with the requirements of standard Internet data services, wireless in the process control environment has stricter quality of service (QoS) requirements. These include more highly reliable transmissions in mobile use cases as well as centralized data analytics, tighter message latency, and lower power consumption.

- Deterministic transmissions in shared wireless bandwidth.

- Low-cost operation.

- Long-term durability.

- High reliability in the harsh radio propagation environment.

In lieu of laying down miles of cables to connect hundreds of field instruments, industrial wireless communication networks provide wireless connections with customized network topology, allow for plug-and-play configuration, and offer lower installation and maintenance costs.

Compared with the requirements of standard Internet data services, wireless in the process control environment has stricter quality of service (QoS) requirements. These include more highly reliable transmissions in mobile use cases as well as centralized data analytics, tighter message latency, and lower power consumption.

Hazardous Area Antennas

Gathering information in hazardous areas is critically important for plants to access. Wireless communications is vital for improved efficiencies, real-time monitoring of machinery and equipment, and the safety and well-being of personnel.

Hazardous area antennas from Analynk Wireless are designed and constructed for very rugged industrial applications. Furthermore, all Analynk hazardous area antennas are UL listed for Class 1, Groups C & D and have ATEX/IECEx Certification. Finally, a range of frequencies are available from 900MHz, 2.4GHz, Cellular, GPS, Iridium and dual bands.

Hazardous area antennas from Analynk Wireless are designed and constructed for very rugged industrial applications. Furthermore, all Analynk hazardous area antennas are UL listed for Class 1, Groups C & D and have ATEX/IECEx Certification. Finally, a range of frequencies are available from 900MHz, 2.4GHz, Cellular, GPS, Iridium and dual bands.

Adapting Wireless Access Points to Hazardous Areas

|

| Cisco 3602E and Hazardous Enclosure |

In autonomous architectures, standalone wireless access points are used to implement all WLAN (wireless local area network) functions. They have to be configured and managed individually and are typically used in smaller installations or stand-alone applications.

|

| Aruba-AP70 and Hazardous Enclosure |

Well Known Manufacturers of Access Points

|

| Meru AP-1020e and Hazardous Enclosure |

|

| Miraki MR72 and Hazardous Enclosure |

Meru Networks is a supplier of wireless local area networks (WLANs) to healthcare, enterprise, hospitality, K-12 education, higher education, and other markets.

|

| Zebra-AP7532 and Hazardous Enclosure |

Zebra Technologies/Motorola manufactures computer systems that include printing, barcode, communication, mobile computing and advanced data capture communications technologies to the manufacturing supply chain, retail, healthcare and government sectors.

Adapting Access Points for Hazardous Area Use

In industrial facilities, hazardous areas are defined as areas where flammable liquids, gases, vapors or combustible dusts exist in sufficient concentration to produce an explosion or fire. In order to locate access points in hazardous areas, specialized access point enclosures fitted with explosion-proof antennae must be used. These enclosures provide UL listed, Class 1, Division 1, Groups C &; D, Zone 1, ATEX Zone 1 antennas (2.4GHz and 5.0GHz), mountings brackets and hardware.

Analynk, a manufacturer of wireless instrumentation in Columbus, OH, offers a wide variety of hazardous area access point enclosures as well as explosion-proof antennas. Contact them by visiting https://analynk.com or calling 614-755-5091.

SensaLynk™ Single & Multi-point Wireless Transmitters, Receivers, and Repeaters

The SensaLynk™ line of industrial wireless products are designed to meet today's increasing demands for greater efficiency, higher reliability and lower cost of ownership. SensaLynk™ wireless technology supports industry standards and protocols and maximizes the flexibility of your process control system while reducing inventory and installation costs.

https://analynk.com

(614) 755-5091

https://analynk.com

(614) 755-5091

HazaLynk™ Wireless Products for Hazardous Areas

The HazaLynk™ Series incorporates a wide selection of wireless hazardous area devices to suit a variety of industrial applications. The product line includes wireless instruments for hazardous areas, hazardous area antennas, hazardous area access point enclosures, and hazardous area RF enclosures that simplify the process of installing field instrumentation, while meeting code requirements for hazardous classified and explosive environments.

https://analynk.com

(614) 755-5091

https://analynk.com

(614) 755-5091

Hazardous Area Classifications

When electrical equipment is used in, around, or near an atmosphere that has flammable gases, vapors, or flammable liquids, there is always a possibility or risk that a fire or explosion might occur. Those areas where the possibility or risk of fire or explosion might occur due to an explosive atmosphere and/or mixture is often called a hazardous (or classified) location/area.

When electrical equipment is used in, around, or near an atmosphere that has flammable gases, vapors, or flammable liquids, there is always a possibility or risk that a fire or explosion might occur. Those areas where the possibility or risk of fire or explosion might occur due to an explosive atmosphere and/or mixture is often called a hazardous (or classified) location/area.Currently there are two systems used to classify these hazardous areas; the Class/Division system and the Zone system. The Class/Division system is used predominately in the United States, whereas the rest of the world generally uses the Zone system.

Class/Division System

Hazardous locations per the Class/Division system are classified according to the Class, Division, and Group.- Class - The Class defines the general nature (or properties) of the hazardous material in the surrounding atmosphere which may or may not be in sufficient quantities.

- Class I - Locations in which flammable gases or vapors may or may not be in sufficient quantities to produce explosive or ignitable mixtures.

- Class II - Locations in which combustible dusts (either in suspension, intermittently, or periodically) may or may not be in sufficient quantities to produce explosive or ignitable mixtures.

- Class III - Locations in which ignitable fibers may or may not be in sufficient quantities to produce explosive or ignitable mixtures.

- Division - The Division defines the probability of the hazardous material being able to produce an explosive or ignitable mixture based upon its presence.

- Division 1 indicates that the hazardous material has a high probability of producing an explosive or ignitable mixture due to it being present continuously, intermittently, or periodically or from the equipment itself under normal operating conditions.

- Division 2 indicates that the hazardous material has a low probability of producing an explosive or ignitable mixture and is present only during abnormal conditions for a short period of time.

- Group - The Group defines the type of hazardous material in the surrounding atmosphere. Groups A, B, C, and Dare for gases (Class I only) while groups E, F, and G are for dusts and flyings (Class II or III).

- Group A - Atmospheres containing acetylene.

- Group B - Atmospheres containing a flammable gas, flammable liquid- produced vapor, or combustible liquid- produced vapor. Typical gases include hydrogen, butadiene, ethylene oxide, propylene oxide, and acrolein.

- Group C - Atmospheres containing a flammable gas, flammable liquid- produced vapor, or combustible liquid- produced vapor. Typical gases include hydrogen sulfide, ethyl either, ethylene, and acetaldehyde.

- Group D - Atmospheres containing a flammable gas, flammable liquid- produced vapor, or combustible liquid- produced vapor. Typical gases include acetone, ammonia, benzene, butane, ethanol, gasoline, methane, natural gas, naphtha, and propane.

Zone System

Hazardous locations per the Zone system are classified according to its Zone. For gas atmospheres electrical equipment is further divided into Groups and Subgroups.The Zone defines the probability of the hazardous material (gas), being present in sufficient quantities to produce explosive or ignitable mixtures.

- Gas

- Zone 0 - Ignitable concentrations of flammable gases or vapors which are present continuously or for long periods of time.

- Zone 1 - Ignitable concentrations of flammable gases or vapors which are likely to occur under normal operating conditions.

- Zone 2 - Ignitable concentrations of flammable gases or vapors which are not likely to occur under normal operating conditions and do so only for a short period of time.

- Group - Electrical equipment used in gas atmospheres is divided into two groups.

- Group I - Equipment used in mines with atmospheres containing methane or gases and vapors of equivalent hazard. (Note: Group I does not apply to offshore and is shown for information purposes only).

- Group II - All other equipment; which is further subdivided into three subgroups.

- Group IIA - Atmospheres containing propane, or gases and vapors of equivalent hazard.

- Group IIB - Atmospheres containing ethylene, or gases and vapors of equivalent hazard.

- Group IIC - Atmospheres containing acetylene or hydrogen, or gases and vapors of equivalent hazard.

Reprinted from The Bureau of Safety and Environmental Enforcement

https://www.bsee.gov

The Move Toward Industrial Wireless Control

Demands for safety, reliability, efficiency, and quality put manufacturing plants under tremendous pressure. Unexpected shutdowns and outages have devastating effects on plant performance. Lost production, increased energy costs, unplanned maintenance costs, and augmented safety concerns are outcomes of equipment failure. Tomorrow's technologies must mitigate these process control realities.

Demands for safety, reliability, efficiency, and quality put manufacturing plants under tremendous pressure. Unexpected shutdowns and outages have devastating effects on plant performance. Lost production, increased energy costs, unplanned maintenance costs, and augmented safety concerns are outcomes of equipment failure. Tomorrow's technologies must mitigate these process control realities.Wireless technology is a serious contributor in the effort to improve plant efficiency, lower risk, and increase productivity. Wireless transmitters are available for monitoring virtual all process variables such as pressure, temperature, level, flow, and density. In harsh environments these devices provide critical performance data transmission around the clock.

Wireless instrumentation provides a compelling argument when you consider installation cost savings and convenience. The cost savings associated with the elimination of wires and cables is estimated to be as high as 70% when compared to the cost using cables for the same application. Furthermore, wireless instruments keep personnel out of hazardous areas, providing additional safety and compliance benefits.

All industries face cost cutting realities as they strive for continuous process improvement. The need to build a better mousetrap is always present. Before widespread adoption of wireless occurs, concerns about reliability, acclimation, and integration must be overcome. But, as deployment costs are reduced, maintenance costs are reduced, employee safety is improved, and environmental compliance is advanced, wireless instrumentation adoption with continue to accelerate in modern process control installations.

Analynk Wireless: Instrumentation for the Process Control Industry

Analynk Wireless is an innovative designer and supplier of wireless instrumentation for the process control industry. Our instruments have been successfully implemented in several applications including temperature measurements 4 to 20mA bridges, discrete inputs/outputs, pulse inputs, lighting and pump controls. These products have been used in both hazardous and non-hazardous locations. Analynk Wireless also manufactures a line of traditional wired instrumentation; see Telmar Instruments for details.

Visit Analynk at Atmosphere 2018

|

| Analynk specializes in hazardous area enclosures for wireless access points. |

Visit Analynk Wireless at their exhibit space, booth D2F, on Monday, Tuesday or Wednesday during the event. Share your wireless connectivity challenges and leverage your own knowledge and experience with Analynk's hazardous area expertise.

Prefabricated Wireless Communications Solution

Wireless transmission of process measurement and control signals has not been new technology for quite some time. In many cases, wireless connection is the installation method of choice over cabled. The benefits in speed of implementation and cost are substantial. That said, as the technology continues to permeate industrial installations of every size, there still remain facilities where it has not made any inroads yet.

When technology is new to the industrial market, especially if it challenges the current way things are done, early adopters with larger scale, higher dollar operations are needed to put the technology into practical use and generate manufacturing volume for the technology producers. If deployment of the technology proves beneficial, the market grows on the consumer and producer sides. With greater efficiency and scale, coupled with growth in the knowledge base throughout the market with increased penetration, costs tend to decrease, while the range of feasible applications and projects grows.

Wireless communication for industrial applications is well beyond the point of early technology adoption. Protocols are in place, products for the transmitting and receiving of wireless process signals are mature. As a stakeholder at any level of a processing operation, you should confidently consider wireless connections between measurement and control or recording devices as part of any new installation or upgrading of existing facilities.

Analynk's wireless demo kit includes a model A750 receiver and A753 transmitter both housed in NEMA 4 enclosures. The kit operates at 900 MHz with full 1W power. Locate the transmitter and receiver at points where you wish to establish a wireless connection. You can provide your own input signal, or use the provided simulator to show that a wireless connection can be established and function in a manner that will give you confidence to move forward with implementation. The kit is useful for testing out possible new locations for distance and signal strength. You will use it as wireless communications expand through your facility. Test the location first, then order the needed wireless equipment. It's a solid and low risk solution.

Wireless communication for industrial applications is well beyond the point of early technology adoption. Protocols are in place, products for the transmitting and receiving of wireless process signals are mature. As a stakeholder at any level of a processing operation, you should confidently consider wireless connections between measurement and control or recording devices as part of any new installation or upgrading of existing facilities.

Analynk's wireless demo kit includes a model A750 receiver and A753 transmitter both housed in NEMA 4 enclosures. The kit operates at 900 MHz with full 1W power. Locate the transmitter and receiver at points where you wish to establish a wireless connection. You can provide your own input signal, or use the provided simulator to show that a wireless connection can be established and function in a manner that will give you confidence to move forward with implementation. The kit is useful for testing out possible new locations for distance and signal strength. You will use it as wireless communications expand through your facility. Test the location first, then order the needed wireless equipment. It's a solid and low risk solution.

An additional use of the prefabricated transmitter and receiver stations is as a temporary portable means of establishing a connection between measurement and control points. The units can even be solar or battery powered, if no power source is available.

Analynk is a manufacturer of both wireless and wired devices for process measurement and control. The company's offering includes a wide array of standard products, as well as integration and customization to meet specific project requirements. Contact the specialists at Analynk to discuss your industrial wireless application requirements.

Analynk is a manufacturer of both wireless and wired devices for process measurement and control. The company's offering includes a wide array of standard products, as well as integration and customization to meet specific project requirements. Contact the specialists at Analynk to discuss your industrial wireless application requirements.

Wireless Process Connections - DIY May Not Be Your Best Option

|

| Analynk can design and fabricate complete systems for establishing wireless process connections. |

The Analynk application team can design and fabricate a complete package solution for your process measurement or wireless connectivity requirement. Share your ideas and challenges with the wireless and process measurement experts, leveraging your own knowledge and experience for a successful project outcome.

Analynk Participation in Aruba Atmosphere 2018

Analynk will be an active sponsoring partner participant at the Atmosphere 2018 conference, held in Las Vegas from March 25 through March 30. The event is organized and hosted by Aruba, a Hewlett Packard Enterprise company. This event provides opportunities for technical training, as well as other resources to keep you and your organization up to date on technology related to wireless networks.

An excerpt from the conference website provides a good synopsis.

Technology is changing so rapidly that it’s near impossible to stay ahead. Don’t rely on Google and YouTube – you should join the best in the industry at Atmosphere 2018. It’s an opportunity to join over 3,000 of your peers to learn, collaborate and influence the direction of Aruba products that deliver enterprise-class wireless, wired, security, location and branch solutions. Be a part of today’s leading innovation machine!Make plans to attend and take advantage of the concentration of available knowledge, all in one place.

At Atmosphere, you’ll experience the technical vision of how you can enable intelligent edge capabilities in your business with the Aruba Mobile First Architecture. Keynotes and hands-on sessions will teach you how to:

- Learn how to turn IT resources into assets for your business

- Close security gaps while supporting workplace flexibility

- Provide the right collaboration tools for organizational creativity

- Help your organization gain an innovation edge

- Embrace the flexibility and scale of cloud and on-premises solutions

Use Signal Repeaters to Overcome Industrial Wireless Transmission Barriers

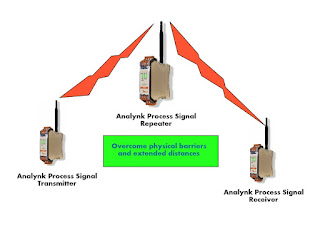

|

| A repeater can be used to overcome barriers to signal transmission, such as distance and structures. |

One, though not the only, solution to overcoming the challenge that can arise due to extended distance or substantial obstacles between the transmitter and receiver is the placement of a repeater. Analynk provides a repeater that can be strategically located between transmitter and receiver to extend the overall transmission distance, or route the signal around obstacles that may otherwise degrade the transmission. The data sheet included below describes how easy it is to apply and provides all the technical details.

Wireless connectivity is an incredibly flexible option for delivery of process data from measurement point to control point. Contact Analynk with your wireless communication challenges and get solid practical solutions.

Fresnel Zones and Industrial Wireless Connections

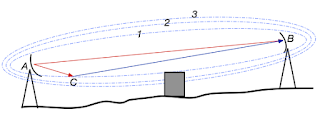

|

| Industrial wireless connections established outdoors across long distances have to consider transmission path geometry. |

Wireless transmission of process signals in industrial settings becomes more prevalent every year, and should continue to do so for quite some time. Many installations are part of networks operating similarly to the wifi you may have in your home, with multiple points communicating via a network control scheme of some sort. The facility is flooded with signal coverage through multiple access points, so there may not be much need to consider signal propagation. This is an oversimplification, but as an operator or implementer, making the actual signal connection is probably not going to be an issue in most cases.

What about the other cases?

|

| Antennas with three Fresnel zones depicted and obstruction that is outside the primary Fresnel zone Courtesy Wikipedia |

An extended transmission distance across an outdoor area requires more understanding of signal propagation and factors that impede successful delivery of process data from transmitter to receiver. One concept that comes into play is the Fresnel zone.

Let's avoid an overly technical approach to Fresnel zones. The purpose of this post is to provide those with limited radio expertise familiarity with the subject of Fresnel zones at a level enabling visualization of the concept, and also to recognize its potential impact on achieving a successful wireless process connection.

We often consider the transmission path between two points to be the familiar "line of sight", an unobstructed straight line between transmitter and receiver. In practice, radio frequency transmission is more accurately characterized by Fresnel zones. Being aware of the shape of the first, or primary, Fresnel zone for your application is an important element in identifying potential obstructions. A general practice is to keep the primary Fresnel zone at least 60% clear of signal obstructions, in order to maintain high wireless link performance.

There are numerous sources of Fresnel zone calculators online, but a strong recommendation to consult with your selected wireless equipment provider is in order here. Combine their expertise at applying their products with your application knowledge to leverage an effective solution.

Subscribe to:

Posts (Atom)