Industrial hazardous area zoning, a crucial element of explosion protection, plays a pivotal role in ensuring safety and compliance with international standards in areas with potentially explosive atmospheres. These areas pose a significant risk due to the potential presence of flammable gases, vapors, dust, or fibers, which can lead to explosive atmospheres. Identifying and managing these zones is therefore of utmost importance. It involves categorizing different facility sections based on the likelihood of an explosive atmosphere being present, thereby facilitating the implementation of appropriate protective measures and the selection of suitable equipment.

A hazardous area is classified into zones according to the frequency and duration of the presence of explosive atmospheres. Zone 0 indicates an area where an explosive atmosphere is continuously present or for long periods. Such environments require stringent controls and specialized equipment designed to operate safely under these conditions. Zone 1, on the other hand, denotes an area where an explosive atmosphere is likely to occur during normal operations. These zones also require robust protective measures and certified equipment. Finally, Zone 2 refers to areas where an explosive atmosphere is not likely to occur in regular operation, and if it does happen, it will only persist for a short duration.

Explosion protection, in the context of industrial hazardous areas, encompasses a range of technical definitions and methods. Among these, intrinsic safety (IS) stands out as a cornerstone of explosion protection. This approach involves limiting the energy, both electrical and thermal, available for ignition within hazardous areas. By ensuring that the energy levels are below the threshold required to ignite an explosive atmosphere, intrinsic safety provides a reliable means of protection. IS equipment is typically designed to be safe even in the presence of two faults, adding an extra layer of safety.

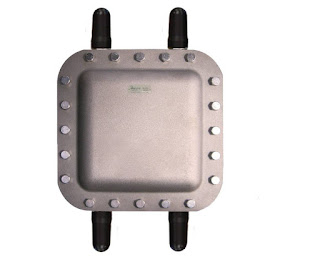

Another critical method is explosion-proof (Ex d) protection. Equipment designed with this method can withstand an internal explosion of an explosive mixture and prevent the propagation of flames or hot gases to the surrounding environment. Explosion-proof enclosures, typically made from robust materials like cast aluminum or stainless steel, contain any explosions that might occur inside, safeguarding the external environment. It's important to note that this protection method is also known as “flameproof” in some standards.

In addition to intrinsic safety and explosion-proof protection, pressurization (Ex p) is an effective method in some hazardous regions. Pressurized enclosures maintain a higher pressure inside the equipment than the surrounding atmosphere, preventing the ingress of flammable gases or dust. This method ensures that the internal atmosphere remains free from potentially explosive mixtures, thus allowing standard equipment to operate safely in hazardous areas. This method is often used for larger enclosures or rooms, and the pressurized air must be clean and dry to avoid introducing new hazards.

Flameproof (Ex d) protection is another vital technique used in hazardous areas. Equipment with flameproof protection must withstand an internal explosion of an explosive mixture and prevent the propagation of this explosion to the external atmosphere. This method relies on robust enclosures that can contain any explosion, ensuring the surrounding area remains unaffected.

Understanding and applying the concept of gas groups is crucial as it guides the design of equipment for use in hazardous areas. Gases are categorized into different groups based on their ignition temperature and explosion pressure characteristics. Group I includes gases found in mining environments (typically methane), while Groups IIA, IIB, and IIC cover gases found in industrial settings, with Group IIC including highly explosive gases such as hydrogen. Equipment designed for use in hazardous areas must be suitable for the specific gas group present, as this determines the level of protection required.

Temperature classification also plays a critical role in explosion protection. Equipment is classified based on the maximum surface temperature it can reach during operation. This classification ensures that the equipment's surface temperature remains below the ignition temperature of any flammable substances present in the hazardous area. These classifications are denoted as T1 to T6, with T1 being the highest ignition temperature and T6 being the lowest. By adhering to temperature classifications, industries can minimize the risk of igniting an explosive atmosphere.

Implementing these explosion protection methods requires a thorough understanding of the hazards in an industrial setting. Risk assessments, such as hazard and operability studies (HAZOP) and layers of protection analysis (LOPA), are essential. Regular inspections and adherence to international standards such as the IEC 60079 series are fundamental to maintaining safety. The IEC 60079 series provides comprehensive guidelines for the classification, installation, maintenance, and inspection of equipment in hazardous areas. For instance, IEC 60079-14 covers the selection and installation of equipment, and IEC 60079-17 addresses inspection and maintenance.

Industrial hazardous area zoning and explosion protection are critical to ensuring safety in environments with potentially explosive atmospheres. By accurately classifying hazardous areas and applying appropriate protection methods such as intrinsic safety, explosion-proof protection, and pressurization, industries can mitigate risks and safeguard both personnel and property. Adhering to international standards and conducting regular assessments further enhances the effectiveness of these measures, creating a safer industrial landscape.