|

| Industrial process signal transmitter |

Rigging up the proper gear to establish wireless transmission of process measurement signals is generally a straight forward task. There are, however, a vastly different set of considerations than those for a wired transmission of the same signal. In order to select the right equipment for the job, some general comprehension of radio signals can be useful.

Radio wave frequencies are below the infrared range on the electromagnetic spectrum, thus their wavelengths are comparatively long. Three things can happen to electromagnetic radiation (radio waves) when encountering a

barrier.

- Reflectance: The wave bounces off the barrier.

- Transmittance: The wave passes through the barrier.

- Absorbance: The wave is stopped.

Which of the three possibilities will occur depends upon a number of factors relating to the signal and the barrier, some of which include:

- The wavelength of the radiation

- The intensity of the radiation hitting the barrier

- The chemical composition of the barrier

- The physical microstructure of the barrier

- The thickness of the barrier

Here is a conglomeration of knowledge items pulled together from a number of public sources that can be applied when considering a wireless installation.

Milliwatts (mW) are the common measurement unit of radio

frequency (RF) power. A logarithmic scale of decibels, referencing 1 mW as the

zero point, provides a useful way to express the comparative strength of RF

signals. Using decibels, a signal strength of 1 mW is registered as 0 dBm. RF

power attenuates according to a logarithmic function, so the dBm method of

expressing RF power enjoys widespread use.

Industrial wireless communications applications in North

America predominantly operate in either the 2.4 GHz or 900 MHz frequency range.

Higher frequency will provide more bandwidth, but at the cost of reduced transmission

distance and obstacle penetration. Lower frequency can require a larger antenna

to attain the same signal gain.

Transmission power is not the only solution for delivering a signal. Low power

signals can be successfully received by sensitive radio equipment. Reducing the

data transmission rate can increase the functional sensitivity of the receiving

equipment, too.

Be mindful of the existence or potential for RF background

noise in your communications environment. A higher level of background noise

can hamper the effectiveness of your equipment. The "noise floor" varies

throughout the frequency spectrum and is generally below the sensitivity level

of most equipment. Industrial environments can sometimes provide unusual conditions

which may warrant a site survey to determine the actual noise floor throughout

the communications area.

|

| Weather conditions can impact signal transmission |

Radio transmission is susceptible to environmental elements on a variable basis. Since the environment can change without notice, it is useful to know the fade margin of a wireless

installation. Fade margin expresses the difference between the current signal

strength and the level at which the installation no longer provides adequate

performance. One recommendation is to configure the installation to provide a

minimum of 10dB of fade margin in good weather conditions. This level can provide sufficient excess signal strength to overcome the diminishing effects

of most weather, solar, and interference conditions.

There are a number of

simple methods to determine whether an installation has at least a 10 dB fade margin. Temporarily

installing a 10dB attenuator on the system antenna, or installing a length of

antenna cable that yields 10dB of attenuation will allow you to determine if

the installation can accommodate 10dB of environmental impact on the signal.

If the system operates suitably with the attenuation installed, you have at

least that much fade margin.

RF signals attenuate with the square of the distance traveled, so if

transmission distance is to be doubled, then the signal power must increase

fourfold.

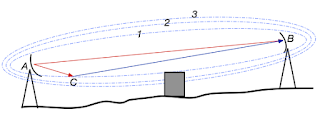

True “line of sight” signal paths are found in a limited number of

installations. The number, type, and location of obstacles in the signal path

can have a significant impact on the signal and contribute to what is referred

to as path loss. Probably the simplest way to reduce the impact of obstacles is

to elevate the antennas above them. Obstacles, in almost every case, are affixed to

the earth, so their interference is reduced by elevating antennas to “see” over

the obstacles.

|

| Wooded areas can be a significant barrier |

When the signal path

extends through an outdoor area, weather conditions have an impact on the path

loss, with higher moisture levels increasing the loss. Large plants, most

notably heavily wooded areas, can impose substantial reduction on RF signals

and may require elevating antennas above the trees or using repeaters to route

the signal around a forested area.

Industrial installations routinely present many reflective

obstacles in the signal path. The transmitted signal may reflect off several obstacles and

still reach the receiving antenna. The received signal strength will be the vector sum of all the paths

reaching the antenna. The phase of each signal reaching the antenna can impact

the total signal strength in a positive or negative way. Sometimes relocating the

antenna by even a small amount can significantly change the strength of the received

signal.

|

| Antenna cable |

Antenna cable contributes to signal attenuation. Use high

quality cable of the shortest length possible to minimize the impact on

performance.

Analynk Wireless has the equipment and expertise to help you deliver wireless process signals across the room, across the street, or across the globe.