Analynk Wireless manufactures hazardous area wireless access point enclosures and hazardous area wireless antennas. Analynk is also a certified UL508A panel manufacturer providing high quality control panels to Ohio and surrounding areas. For more information, visit the Analynk website here or call 614-755-5091.

Product Options Round Out Fulfillment of Application Requirements

Analynk Wireless, in addition to their standard products, can provide an extensive range of value added services to help customers quickly and effectively fulfill project requirements involving wireless communications and process control. Share your challenges with the wireless and process control experts at Analynk, combining your process knowledge with their wireless and control expertise to develop effective solutions.

Refractometry Applications in Industry

|

| In-line refractometer for industrial processing Courtesy Electron Machine |

The ultimate focus of industrial refractometry is to describe what is in a final product or output of a process step. A field which relies directly on the results of refractometry is gemology. Gemological refractometry is crucial for accurately identifying the gemstones being classified, whether the gemstones are opaque, transparent, or translucent.

Other common examples of industrial refractometry uses are measuring the salinity of water to determine drinkability; figuring beverages’ ratios of sugar content versus other sweeteners or water; setting eye-glass prescriptions; understanding the hydrocarbon content of motor fuels; totaling plasma protein in blood samples; and quantifying the concentration of maple syrup. Regarding fuels, refractometry scrutinizes the possible output of energy and conductivity, and for drug-testing purposes, refractometry measures the specific gravity, or the density, of human urine. Regarding food, refractometry has the ability to measure the glucose in fruit during the fermentation process. Because of this, those in food services know when fruit is at peak ripeness and, in turn, also understand the most advantageous point in the fruit’s “lifetime” to put it on the market.

The determination of the substance composition of the product examples listed above all speak to the purpose of quality control and the upholding of standardized guidelines; consumers rely on manufacturers not only to produce these products but also to produce these products consistently and identically every single time. Therefore, the success of commercialism, etc. is dependent on maintaining the standards for the composition of substances, i.e. industrial refractometry.

Equipment manufacturers have developed numerous refractometer configurations tailored to specific use and application. Each has a set of features making it the advantageous choice for its intended application. Product specialists can be invaluable sources of information and assistance to potential refractometer users seeking to match the best equipment to their application or process.

Analynk manufactures wireless communications equipment to connect process measurement instruments with remotely located process monitors and controllers. Their products enable customers to make connections across the room, across the plant, across the highway, and around the globe.

Defending Industrial Control Systems From Cyber Threats

|

| Industrial control system data cannot be protected by a fence around the plant site. |

The National Cybersecurity and Communications Integration Center, part of the US Department of Homeland Security, ...

serves as a central location where a diverse set of partners involved in cybersecurity and communications protection coordinate and synchronize their efforts. NCCIC's partners include other government agencies, the private sector, and international entities. Working closely with its partners, NCCIC analyzes cybersecurity and communications information, shares timely and actionable information, and coordinates response, mitigation and recovery efforts. (from www.us-cert.gov/nccic)

The Industrial Control Systems Cyber Emergency Response Team (ICS-CERT) is a division under NCCIC. It has published a set of seven basic steps toward establishing a more secure industrial control system. I have included the publication below, and it is interesting and useful reading for all involved in industrial process control.

Having a fence around an industrial site, with a guarded entry gate, no longer provides the level of security needed for any industrial operation. Read the seven steps. Take other actions to build your knowledge and understanding of the risks and vulnerabilities. Cybersecurity is now another layer of design tenets and procedures that must be added to every control system. It will be a part of your company's best practices and success, now and in the future.

There are uncountable legacy controllers and communications devices throughout industrial America. All need to be reassessed for their vulnerability in the current and upcoming security environment. When reviewing your processes and equipment, do not hesitate to contact Analynk Wireless for assistance in your evaluation of our products.

Solar Powered Wireless Communications for Industrial Process Measurement and Control

|

| Analynk Model A650 Solar Power Supply |

The power supply unit comes complete with solar panel, battery, charge controller, and NEMA 4 enclosure. Options are available to accommodate specific installation requirements. Custom units can be designed for larger power requirements and other special applications.

The data sheet below provides more detail. Share your wireless process measurement and control connectivity challenges with Analynk for effective solutions.

Process Connections - Wireless is Simple Solution to Many Challenges

|

| Wireless connections for industrial process signals |

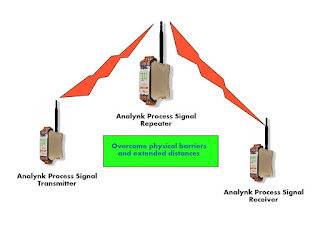

Industrial wireless transmitters, receivers, and repeaters can be applied in place of wires, cables, conduit, trenches, overhead supports, and all the other hardware associated with a wired installation. Data is gathered using whatever process measurement hardware you prefer, just specify commonly used output signals like 4-20 mA, or a host of others. Connect the measuring device output to the transmitter input. Locate a receiver where you want the sensor information delivered. The transmitter converts the sensor analog signal to digital and the receiver converts back to analog. The connection can be accomplished in a very short amount of time without disturbance to the real estate between the two points.

How can I tell if the wireless connection can be accomplished without interference?The transmission is accomplished in either the 900 MHz or 2.4 GHz band, delivering adequate range and power for most facility-wide applications. Obstructions can be overcome with the use of a strategically located repeater.

What about power needed to operate the sensors and wireless equipment?Most process sensors have very small power requirements, as do the Analynk transmission units. Power, if line voltage is not available at the location, can be provided by batteries, or combination of battery and photovoltaic. Little power needs to be provided for operation.

There may be simple and effective wireless solutions to many of your remote monitoring challenges. Don't assume it is difficult, it is not. Don't assume it is expensive, it is not. Share your ideas and challenges with the experts at Analynk. Combining your facility and process knowledge with their technology and product expertise will lead to effective solutions.

Wireless Access Points Installed in Hazardous Locations

|

| Hazardous area wireless access point enclosure with explosion proof antennas. |

Analynk manufactures rated enclosures for industrial wireless access points, facilitating their installation in hazardous locations. Each access point enclosure is specifically targeted and designed to provide easy installation of specific wireless access points from a range of manufacturers. Every model is provided with UL listed explosion proof antennas, a mounting bracket designed for the target access point, and RF cables to make the antenna connections. Enclosures have penetrations specifically located to accommodate the target access point.The current offering accommodates a range of units from Symbol, Cisco, Meru, Aruba, HP, and Motorola, with more models added regularly to accommodate additional wireless access points.

The newly added AP620 is designed for the Motorola/Zebra AP-7532 Access PointAnalynk Wireless specializes in industrial wireless communications. Your wireless communication challenges are welcome at Analynk, so make contact and share your application requirements. Combining your process expertise with Analynk's product specialization will produce an effective solution.

Increasing Generator Set Starting Reliability

|

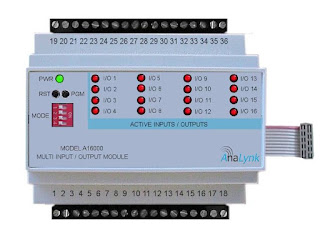

| Genset monitoring application is ideal for use of the A16000 Expansion Module |

A generator set is a risk mitigation asset, intended to prevent loss of operations when certain adverse conditions occur. Power failures are generally infrequent, so the equipment remains idle most of the time. Automatic controls can test run the unit periodically, but continuous monitoring of a few points on the equipment can provide information that increases the assurance that the unit will start when commanded. Delivering the data to an operations center for monitoring and storage for analysis provides a supervisor a snapshot of unit readiness in real time, anytime.

Some items to monitor that can increase your assessment of startup reliability:

- Fuel Level - Clearly, knowing the current fuel level is useful. Being able to read the engine fuel level from your operations center saves technician time and provides a continuous means of estimating available generator runtime.

- Engine Block Heater - Measure the current flowing to the engine block heater to make sure the heater is functioning properly.

- Battery - A voltage reading provides indication of battery health.

- Ambient Temperature - While not essential, logging temperature along with the other items can provide some useful data that may reveal some correlations.

- Generator Controller Fault Indicators - If the generator control system provides any outputs that will indicate detection of a fault, monitoring their status at the facilities office brings the data to where it can be acted upon immediately.

There may be other aspects of a generator set that can be monitored during standby to increase the assurance of a startup on command. A careful assessment of each system in place will reveal the possibilities.

Analynk manufactures all the transmitters and sensors necessary to deliver the data points needed. With many generators located remotely from the point where the data should be delivered, Analynk's wireless communications products can be employed to deliver all the data from the generator to the facilities or operations center without having to install any cabling between the locations.

Reach out to Analynk with your performance or process monitoring and data delivery challenges. Combing your process and facilities knowledge with their product application expertise will produce effective solutions.

Subscribe to:

Comments (Atom)